Best Food Safe Paints & Finishes for Wood, Ceramic, Metal & Glass

When you’re giving a personal touch to cutting boards, serving trays, mugs, or even metal kitchen tools, paint might seem like a harmless way to enhance their look. But not all paints are created equal—especially when it comes to items that come in contact with food.

While many paints on the market are labeled “non-toxic” or “low-VOC,” that doesn’t necessarily make them food-safe. True food-safe finishes must meet strict regulatory standards to ensure they don’t leach harmful chemicals, flake off, or contaminate your food over time.

Get the Fail-Safe Paint Color Playbook (Free PDF)

36 proven colors • 8 ready palettes • trim & sheen guide • printable testing cards.

Whether you’re refinishing a wooden salad bowl, customizing ceramic plates, or sealing a metal breadbox, choosing the right coating is crucial—not just for aesthetics, but for safety. In this guide, we’ll explore the best food-safe paints and finishes tailored to different materials—wood, ceramic, metal, and glass—so you can craft with confidence and peace of mind.

What Is Food‑Safe Paint (and Why It’s Different)

When we talk about food-safe paint, we’re referring to coatings that are specifically formulated and tested not to leach harmful chemicals when they come into contact with food. This goes far beyond “non-toxic” labels. True food-safe paints must meet direct contact standards—something most household paints, even zero-VOC types, don’t qualify for.

The Legal Definition: What the Regulations Say

Food-safe coatings must comply with official standards that vary slightly between the U.S. and international agencies. These include:

- FDA 21 CFR 175.300 – Regulates resinous and polymeric coatings in the U.S., specifying which ingredients are acceptable for direct food contact (used in products like canned foods or beverage liners).

- GRAS (Generally Recognized As Safe) – Refers to substances that have been approved for food contact use based on scientific consensus.

- EN-71 (European Toy Safety Standard) – Often referenced for paints used on items like highchairs or toys, ensuring that coatings do not release heavy metals or toxins when licked or mouthed.

- EU Regulation 10/2011 – Governs plastics and coatings intended for direct contact with food in the European Union.

These standards evaluate ingredients, leaching potential, and safety under common use scenarios—like exposure to heat, moisture, and utensils.

Why Regular Paint Isn’t Safe—Even If It’s “Non-Toxic”

Standard household paints (such as latex, acrylic, or enamel) often include additives for flexibility, adhesion, or durability. These may include:

- Plasticizers

- Preservatives

- Formaldehyde-releasing agents

- Solvents or pigments that aren’t stable under moisture or heat

Even when these paints are labeled non-toxic or low-VOC, they can still leach chemicals when in direct contact with food—especially under heat, knife abrasion, or acidic conditions. Worse yet, most aren’t designed to fully cure for food-use scenarios, leaving a flexible film that can degrade over time.

Types of Food Contact

It’s important to understand the level of contact your project will have with food. Regulations differ depending on how the item will be used:

- Direct food contact – Items like cutting boards, serving bowls, or ceramic plates that come into actual contact with food.

- Incidental contact – Trays, cabinet interiors, or surfaces that might occasionally touch food but aren’t meant to serve or store it.

- Non-contact decorative items – Signs, exterior handles, furniture legs—basically anything that won’t come near food.

Knowing the level of contact helps determine how rigorous your material safety needs to be. Direct contact requires full food-grade compliance; incidental contact might allow for toy-safe or sealed options.

Top Food‑Safe Paints & Finishes by Surface

Not all food-safe finishes are created equal. Some are great for wood but won’t work on glass; others may cure safely on ceramic but require high heat to set. Here’s a curated list of the safest and most effective paints and coatings categorized by surface type and backed by real-world performance.

1. Milk Paint + Food-Safe Oils (for Wood)

Best for: Wooden bowls, serving trays, cutting boards (with topcoat)

Milk paint is one of the oldest, most natural finishes still in use. Made from milk protein (casein), lime, and earth pigments, it’s free of synthetic binders or solvents.

Why it’s food-safe: When unsealed, it’s considered non-toxic but porous. To make it food-safe, you must seal it with a food-grade oil like:

- Pure Tung Oil (not heat-treated or thinned)

- Hemp Oil or Raw Walnut Oil

- AFM AcriGlaze (Toy Safe certified)

Application tips:

Get the Fail-Safe Paint Color Playbook (Free PDF)

36 proven colors • 8 ready palettes • trim & sheen guide • printable testing cards.

- Stir thoroughly and apply with a brush

- Let dry and cure for 24–48 hours

- Follow with several thin coats of your chosen food-safe oil

- Cure for at least 7–30 days (depending on oil type)

Not suitable for: Surfaces exposed to excessive water or heat without proper sealing.

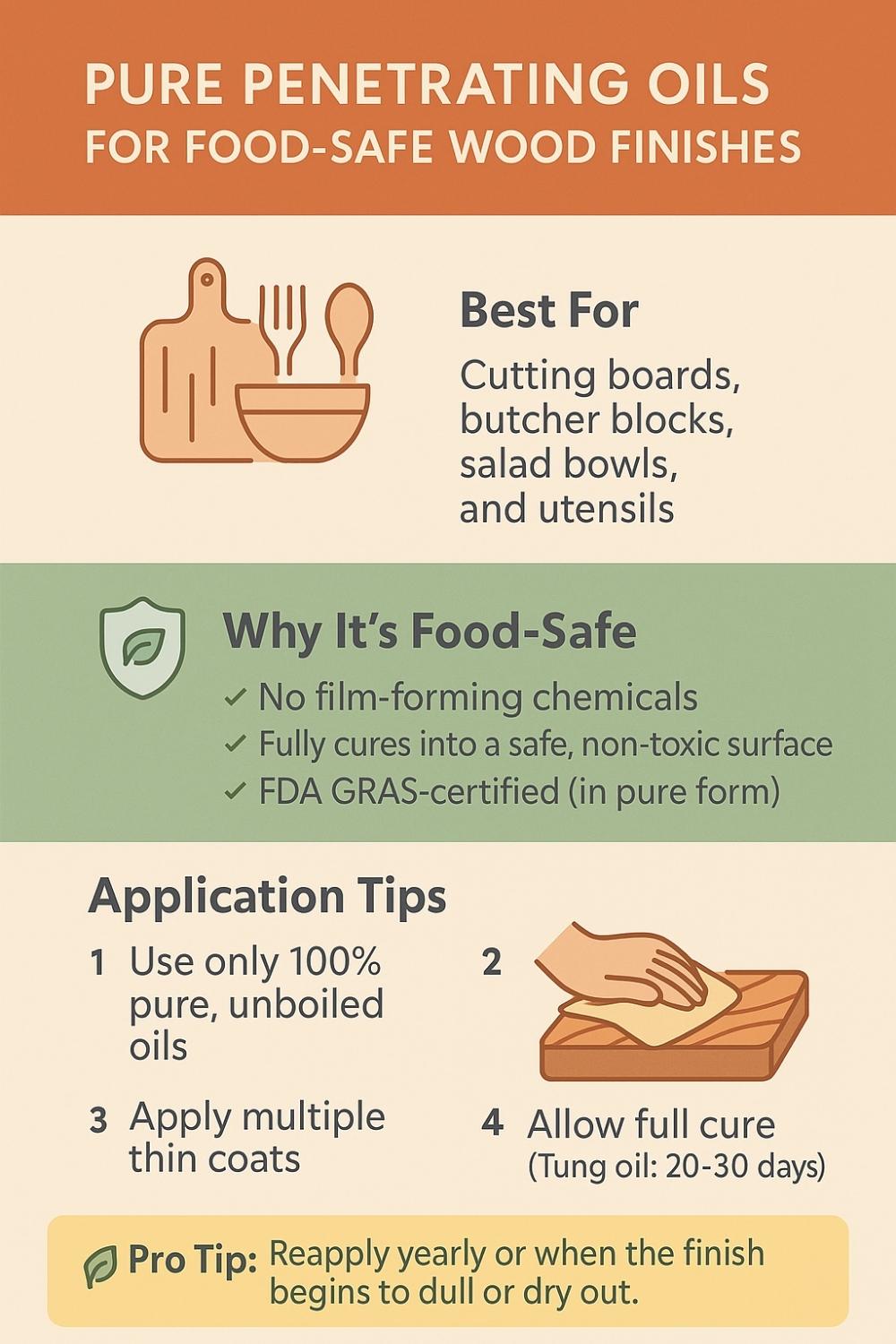

2. Pure Penetrating Oils (Tung, Linseed, Walnut)

Best for: Cutting boards, butcher blocks, salad bowls, and utensils

These oils penetrate deep into the wood and harden into a durable, water-resistant finish. They are GRAS-certified (Generally Recognized As Safe) by the FDA when used in pure form—no additives or drying agents.

Why it’s food-safe:

- No film-forming chemicals

- Cures into a non-toxic finish after full polymerization

Application tips:

- Use only 100% pure, unboiled oils

- Apply in multiple thin coats, allowing each to soak in

- Buff off excess and allow to cure fully (Tung oil may take 20–30 days)

Pro tip: Reapply yearly or when the finish begins to dull or dry out.

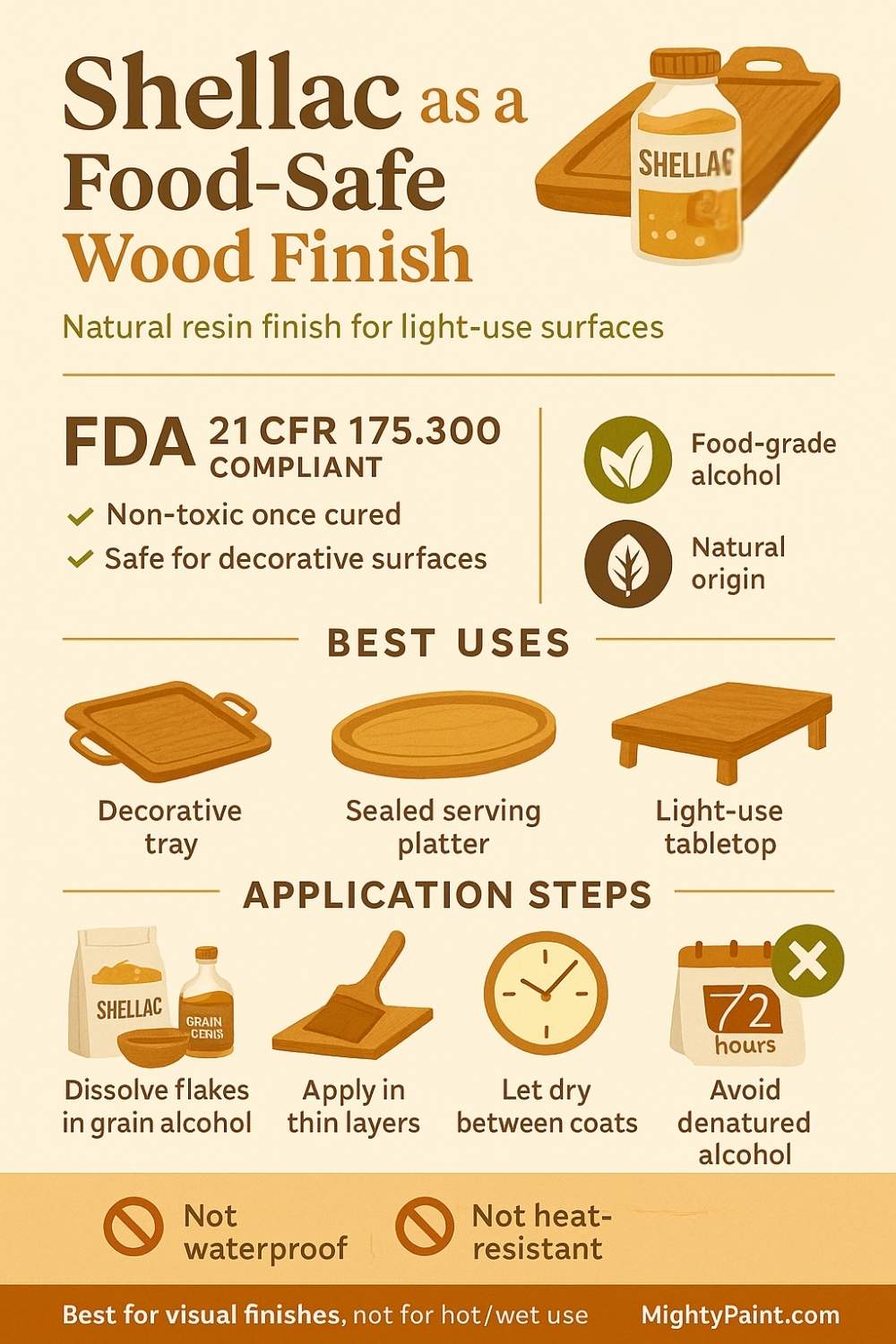

3. Shellac (Natural Resin + Food-Grade Alcohol)

Best for: Decorative wooden trays, light-use serving platters, sealed tabletops

Shellac is made from a resin secreted by the lac bug and dissolved in ethanol. It’s been used for centuries as a coating for food, candy, and even pharmaceutical capsules.

Why it’s food-safe:

- Recognized by the FDA under 21 CFR 175.300

- Non-toxic once cured and evaporated

Application tips:

- Only use flakes dissolved in 190-proof grain alcohol (not hardware store denatured alcohol)

- Apply in thin layers with a brush or cloth

- Dries quickly; allow a full 72 hours for complete curing before food contact

Note: Shellac is not waterproof or heat-resistant—avoid high-moisture or hot surfaces.

Get the Fail-Safe Paint Color Playbook (Free PDF)

36 proven colors • 8 ready palettes • trim & sheen guide • printable testing cards.

4. AFM Safecoat Paints and Sealers

Best for: Wood surfaces with incidental food contact, children’s furniture, trays, trim

AFM Safecoat is a line of low-VOC, non-toxic paints and finishes developed for chemically sensitive environments. While not marketed directly for food-contact surfaces, many of their products meet EN-71 (Toy Safe) and interior air safety standards, making them a practical choice for items near food—but not those in direct contact with it.

Why it’s (conditionally) food-safe:

- Certified non-toxic and Toy Safe

- Often used on tabletops, highchairs, or food-adjacent areas

Best products in the line:

- Safecoat Acrylacq (clear low-sheen acrylic for wood)

- AFM MetalCoat Primer for food-adjacent metal or trim

- Safecoat Polyureseal BP for durable wood protection

Application tips:

- Apply per label with proper dry time between coats

- Not recommended for unsealed cutting boards or utensils

Good to know: Excellent for home surfaces near food—such as dining tables or pantry shelving.

5. Fakolith FoodGrade Enamel & FK-45/100 Epoxy

Best for: Direct food contact on metal, wood, ceramic, and 3D-printed parts

Fakolith’s certified FoodGrade Enamel and Epoxy Coatings are used in commercial kitchens, food factories, and hospitals across the EU. These are two of the only paints to carry both FDA 21 CFR 175.300 and EU 10/2011 certifications for direct food contact.

Why it’s food-safe:

Get the Fail-Safe Paint Color Playbook (Free PDF)

36 proven colors • 8 ready palettes • trim & sheen guide • printable testing cards.

- Explicitly tested and certified for surfaces that touch food

- Antimicrobial, chemical-resistant, and extremely durable

Two versions to choose from:

- Dispaint FoodGrade Acrylic Enamel: quick-drying, matte/satin finish

- FK-45/100 Epoxy: two-part coating for industrial-grade protection

Application tips:

- Requires surface prep and accurate mixing (for epoxy)

- Use appropriate brushes or rollers rated for chemical coatings

- Follow curing times precisely to ensure compliance and durability

Where to buy: Direct from specialized food-safe paint retailers online or from Fakolith distributors.

6. Pebeo Porcelaine 150 (for Ceramic & Glass)

Best for: Decorative plates, mugs, glassware—not cutting surfaces

Get the Fail-Safe Paint Color Playbook (Free PDF)

36 proven colors • 8 ready palettes • trim & sheen guide • printable testing cards.

Pebeo Porcelaine 150 is a water-based enamel specifically designed for use on ceramic, porcelain, and glass. Once baked (in a conventional oven), it forms a durable, dishwasher-safe surface. While it’s labeled as non-toxic and safe for indirect food contact, users and artists often use it on the exterior of cups or decorative dishware.

Why it’s food-safe (conditionally):

- After baking at 300°F for 35 minutes, the finish is dishwasher- and water-resistant

- Free from heavy metals and formaldehyde

- Manufacturer advises: safe for exteriors or rims but not intended for plate centers or cutting zones

Application tips:

- Use a fine brush for clean edges

- Cure per label directions; avoid microwave or high-heat exposure post-bake

- Avoid using on areas that will be directly cut or scraped with utensils

Styling tip: Excellent for adding decorative patterns to vintage ceramics or custom glass mugs.

Material-Specific Recommendations & Use Guide

The safest finish depends not only on the type of surface you’re painting but also on how it will interact with food. Here’s a simplified reference guide to help you choose the right product for each surface:

| Surface | Recommended Product(s) | Seal Required? | Notes |

|---|---|---|---|

| Wood – Cutting Boards / Utensils | Pure Tung Oil, Raw Linseed Oil, Raw Walnut Oil | No | Avoid paint or film-forming sealers. Reapply oil regularly. |

| Wood – Serving Trays / Light Use | Milk Paint + Food-Safe Oil (Tung/Hemp/Walnut), Shellac | Yes | Always seal milk paint with food-grade oil. Shellac for light use only. |

| Wood – Highchairs / Trim / Incidental Use | AFM Safecoat Acrylacq or Polyureseal BP | No (already sealed) | Good for toys, trays, or furniture that touches food occasionally. |

| Ceramic / Porcelain | Pebeo Porcelaine 150 (oven-cured) | No (self-sealing) | Use only on outer surfaces. Avoid eating or cutting areas. |

| Glass | Pebeo Porcelaine 150 (oven-cured) | No | Decorative only. Apply on exteriors, not for food-contact interiors. |

| Metal – Food Contact Surfaces | Fakolith FoodGrade Epoxy or Enamel | No | Certified for direct contact. Requires precise mixing and curing. |

| Metal – Trays / Handles / Non-Contact | AFM Safecoat Metal Primer + topcoat | Optional | Use for incidental food contact or decorative purposes. |

| 3D-Printed Parts / Displays | Fakolith FK-100 FoodGrade Epoxy | No | Ideal for food displays or specialty components. |

Quick Tip: If food will be cut, stirred, or cooked on a surface—only use penetrating oils or certified FDA food-contact epoxies. Painted or decorative finishes may degrade under repeated use, even if they’re labeled non-toxic.

Important User Guidelines & Regulations

Choosing a food-safe paint or finish is only half the battle. Proper use, curing, and product verification are critical to ensuring long-term safety and compliance.

Understand Regulatory Labels

When evaluating whether a paint or finish is truly food-safe, look for these indicators:

- FDA 21 CFR 175.300: U.S. regulation for resinous and polymer coatings intended for food contact. If a product claims compliance, it should cite this directly.

- GRAS: “Generally Recognized As Safe” substances, approved based on expert consensus or historical use (e.g., pure Tung oil).

- EN-71/3 Toy Safe: Used to confirm non-toxicity in products that may be mouthed by children—useful for items with incidental food contact (like trays or highchairs).

- EU 10/2011: European equivalent of food-contact-safe standards—common for products like Fakolith enamel and epoxy.

Important: “Non-toxic,” “low-VOC,” or “eco-friendly” does not automatically mean food-safe. These labels are often about air quality, not ingestion safety.

Cure Time Is Everything

Even safe finishes can be harmful if not properly cured. Many penetrating oils and natural coatings need time to polymerize and harden before they’re food-safe.

General cure time guidelines:

- Tung Oil: 7 to 30 days

- Shellac: 72 hours

- AFM Safecoat Polyureseal: 5–7 days

- Pebeo Porcelaine 150: 35-minute oven cure

- Fakolith Epoxy: varies by formula; follow label

Avoid washing, using, or storing food on surfaces before full curing—especially under warm or moist conditions, which can accelerate breakdown or leaching.

Surfaces to Never Paint for Food Use

No matter how safe the product, some surfaces aren’t good candidates for food-safe painting due to durability, repeated wear, or heat exposure.

Avoid painting:

- Cooking pots and pans (even on exteriors)

- Cutting zones on plates or ceramic dishes

- Microwave interiors or toasters

- Surfaces used with acidic or oily foods (unless sealed with certified coatings)

Best Practices Summary

- Always verify third-party certifications (not just marketing claims)

- Never mix sealers, solvents, or thinners unless the label explicitly allows

- Store and use food-contact items away from harsh detergents or dishwashers unless the finish is rated dishwasher-safe

Real‑World Wisdom: DIY Tips & Community Insights

Beyond the product labels and regulations, everyday users have tested these paints and finishes in real kitchens and workshops. Their experiences offer valuable lessons in what works—and what doesn’t—when using food-safe coatings at home.

Milk Paint + Oil: A Trusted DIY Combo

“Milk Paint is considered food safe … if you cover whatever paint with a food safe oil, like Tung or Hemp Oil.”

—Reddit user, r/Woodcarving

Milk paint alone is porous and chalky. While it’s safe in its raw form, it must be sealed to handle food exposure and moisture. DIYers frequently use 100% pure Tung oil or raw hemp oil to seal it. The key is applying multiple light coats and letting it cure for weeks.

Real-world tips:

- Always use a brush, not spray, for more control and even coating.

- Don’t rush curing—30 days might feel excessive, but it prevents stickiness and finish failure.

Shellac’s Old-School Safety—With a Catch

Shellac is widely used on wooden kitchenware, but success depends on the purity of ingredients. Reddit crafters and woodworkers recommend buying food-grade flakes and dissolving them in grain alcohol (like Everclear). Avoid shellac sold in hardware stores unless it’s clearly labeled food-safe.

Community lesson:

Avoid shortcuts—shellac in pre-mixed cans may contain denatured alcohol, which isn’t safe for food surfaces.

Ceramic Paints: Stick to Decorative Zones

Many users experimenting with ceramic paints like Pebeo Porcelaine 150 love their ease of use, but commonly note:

Get the Fail-Safe Paint Color Playbook (Free PDF)

36 proven colors • 8 ready palettes • trim & sheen guide • printable testing cards.

“You can use it on cups and plates, but not where utensils scrape food. Only decorate edges and exteriors.”

Even after baking, these paints are best suited for mugs, saucers, or dish rims—not the eating surface. Artists often combine Pebeo with clear glazes for added durability, but this isn’t food-safe unless certified.

Oils Need Maintenance

Even pure oils like Tung or Walnut aren’t one-and-done solutions. Several woodworking forums stress that oils need regular reapplication—especially on cutting boards or items exposed to water and soap.

DIY advice:

- Wipe on a fresh coat every 3–6 months

- Use 400–600 grit sanding pads between coats for a smoother finish

- Never use mineral oil from hardware stores unless labeled as food-grade

Quick Decision Flowchart: What Finish Do I Need?

Choosing the right food-safe paint or finish doesn’t have to be overwhelming. Use this simple guide to figure out the best product based on the surface you’re working with and how it will be used.

✅ Step 1: What’s the Surface?

- Wood

- Ceramic / Porcelain

- Metal

- Glass

- 3D-Printed Plastic or Resin

✅ Step 2: Will Food Touch It Directly?

- Yes → Continue below

- No (only incidental contact) → Use low-VOC paints (e.g., AFM Safecoat), Toy Safe finishes, or decorative enamel

✅ Step 3: Choose a Finish Based on Your Surface

| Surface | Direct Food Contact? | Recommended Finish |

|---|---|---|

| Wood | Yes | Pure Tung oil, Raw Linseed, Milk Paint + Oil, Shellac |

| Wood | No | AFM Safecoat Acrylacq or Polyureseal |

| Ceramic | Yes (limited) | Pebeo Porcelaine 150 (edges only, oven-cure required) |

| Ceramic | No | Any water-based enamel labeled non-toxic |

| Metal | Yes | Fakolith FoodGrade Enamel or FK-45/100 Epoxy |

| Metal | No | AFM MetalCoat primer + low-VOC topcoat |

| Glass | Yes (limited) | Pebeo Porcelaine 150 (rim/exterior only, not base or interior) |

| 3D-Printed Part | Yes | Fakolith FK-100 FoodGrade Epoxy |

✅ Step 4: Final Check

- Is the product explicitly labeled as FDA or GRAS compliant?

- Will it fully cure before use? (check manufacturer’s cure time)

- Are you using compatible sealers, if required?

If you’ve answered yes to all, you’re ready to finish your project safely!

Relevant & Helpful Resources

- FDA Title 21 CFR 175.300 – Resinous and Polymeric Coatings

Official U.S. regulation defining acceptable materials and conditions for coatings intended for direct food contact. - My Chemical-Free House – Food-Grade Paints & Clear Coatings Guide

In-depth, regularly updated guide listing food-safe paints, oils, sealers, and finishes with clarity around ingredients and certifications. - AFM Safecoat Official Website

Source of low-VOC, non-toxic paints and finishes including Toy Safe certified products, suitable for food-adjacent surfaces. - Pebeo Porcelaine 150 Product Page

Manufacturer’s guide for using oven-cured, food-safe ceramic paint, including curing instructions and safety recommendations. - FoodGradePaint.com – Fakolith Certified Food-Safe Coatings

Supplier and information hub for FDA- and EU-certified food-contact epoxies and enamels used in both residential and industrial settings.