Lacquer vs Polyurethane: What Is the Difference for Wood Finishes?

If you’re tackling a wood project, picking the right finish really matters. Lacquer and polyurethane are both big names in the woodworking world, but they’re not at all the same. Each protects wood and adds a nice look, but they do it in their own ways.

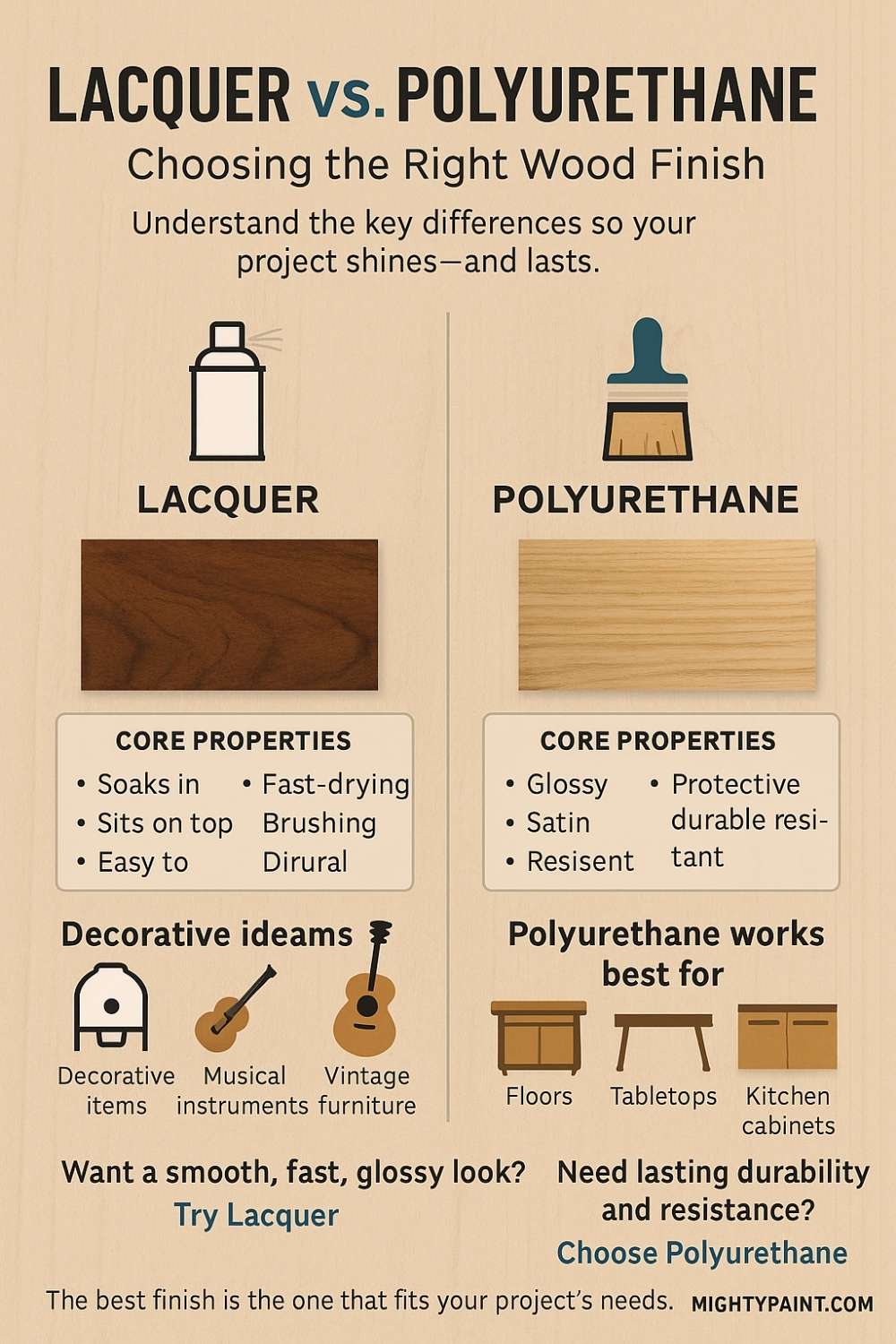

The main difference: lacquer soaks into the wood and fuses with earlier coats, while polyurethane forms a hard, plastic-like layer right on top. This changes how you apply them, how they look, and how long they last.

Get the Fail-Safe Paint Color Playbook (Free PDF)

36 proven colors • 8 ready palettes • trim & sheen guide • printable testing cards.

Knowing what sets these finishes apart helps you pick what’s right for your project. There’s no one-size-fits-all answer, but understanding their quirks saves headaches later.

What Is Lacquer?

Lacquer dries super fast and leaves a hard, glossy surface. It soaks into the wood and bonds with previous coats. You’ll find all sorts—nitrocellulose, acrylic, water-based, and even versions made for brushing.

Lacquer Composition and Types

Lacquer’s basically synthetic resin dissolved in quick-evaporating solvents. Here’s the lineup:

Nitrocellulose lacquer is the classic. It’s made from cellulose, giving wood a clear, deep look.

Acrylic lacquer uses acrylic resin, so it keeps its color and doesn’t yellow like nitrocellulose sometimes does.

Water-based lacquer skips a lot of the harsh chemicals. It dries clear and doesn’t stink up your workspace.

Brushing lacquer dries slower, which is great if you’re using a brush instead of a sprayer. It gives you a bit more time to work.

Most lacquers are meant for spraying, but brushing lacquer is handy for small or detailed stuff.

Properties and Characteristics of Lacquer

Your lacquer finish dries to the touch in as little as 5–30 minutes. That’s fast compared to most finishes.

Lacquer goes on thin. Each new coat melts into the last, so you get one smooth layer instead of a stack of separate ones.

No need to sand between coats—new lacquer bonds right into the old.

Key properties:

Get the Fail-Safe Paint Color Playbook (Free PDF)

36 proven colors • 8 ready palettes • trim & sheen guide • printable testing cards.

- Dries crazy fast

- Can get super glossy

- Stands up to scratches (once fully cured)

- Easy to fix if you mess up

Lacquer really makes wood grain pop. You can go from mirror-gloss to matte, whatever suits your project.

Common Uses of Lacquer

Lacquer shines on fine furniture and detailed work. You’ll spot it on:

- Cabinets and kitchen stuff

- Picture frames

- Musical instruments

- Antique furniture

The finish is silky and feels great to the touch—ideal for things people handle a lot.

But for heavy-use floors? Not so much. The thin coating can wear down fast.

Lacquer’s mostly an indoor choice. It doesn’t love rain, sun, or wild weather swings.

Need to finish a project in a hurry? Lacquer’s quick drying lets you stack up multiple coats in one day.

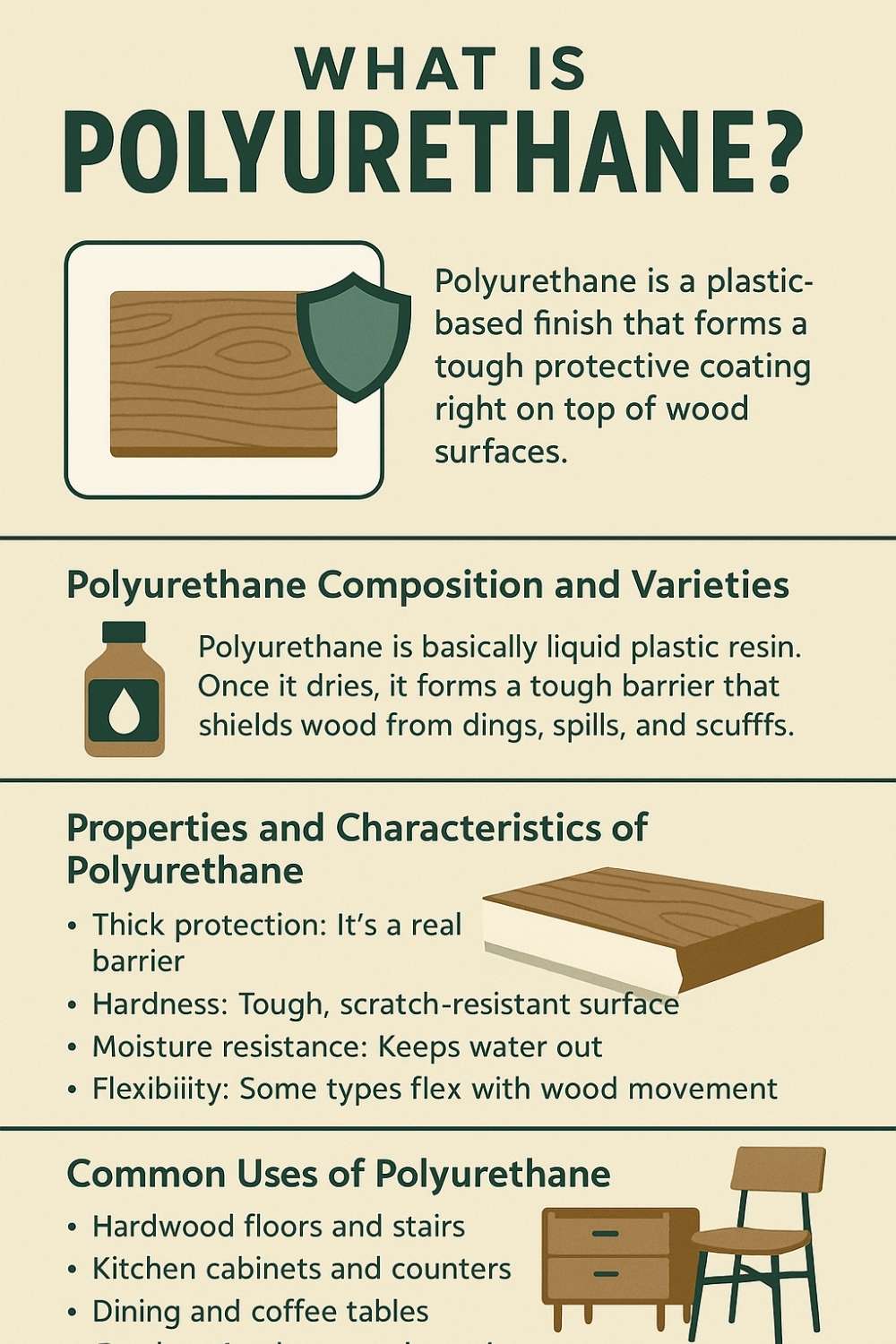

What Is Polyurethane?

Polyurethane is a plastic-based finish that forms a tough protective coating right on top of wood surfaces. You’ll find both oil-based and water-based varieties, each with its own perks.

Polyurethane Composition and Varieties

Polyurethane is basically liquid plastic resin. Once it dries, it forms a tough barrier that shields wood from dings, spills, and scuffs.

Here’s the breakdown:

Oil-Based Polyurethane:

- Dries slowly—think up to 24 hours

- Gives wood a warm, amber tone

- Super durable and scratch-resistant

- Smells pretty strong and has more VOCs

Water-Based Polyurethane:

Get the Fail-Safe Paint Color Playbook (Free PDF)

36 proven colors • 8 ready palettes • trim & sheen guide • printable testing cards.

- Dries fast (2–4 hours between coats)

- Stays clear—no yellowing

- Lower odor, easy water cleanup

- More eco-friendly

Both come in a bunch of sheens: high-gloss, semi-gloss, satin, matte—you pick what fits your style.

Properties and Characteristics of Polyurethane

Polyurethane forms a thick, solid coat that sits right on top of the wood. It’s a shield against water, scratches, and everyday abuse.

It’s known for serious durability. Floors, tabletops—poly can handle it.

Key properties:

- Thick protection: It’s a real barrier

- Hardness: Tough, scratch-resistant surface

- Moisture resistance: Keeps water out

- Flexibility: Some types flex with wood movement

You’ll want to sand between coats, since each layer just sits on top of the last. It’s a bit more work, but it helps the finish stick.

Common Uses of Polyurethane

Polyurethane is made for surfaces that see a lot of action. It’s the go-to for high-traffic spots at home.

Inside the house:

- Hardwood floors and stairs

- Kitchen cabinets and counters

- Dining and coffee tables

- Bookshelves and built-ins

Outside, too:

- Outdoor furniture (if it’s UV-protected)

- Decks and railings

- Window trim and doors

It’s forgiving, too. You can brush, wipe, or spray it—whatever works for your project size and patience level.

Get the Fail-Safe Paint Color Playbook (Free PDF)

36 proven colors • 8 ready palettes • trim & sheen guide • printable testing cards.

Price-wise, expect $10–25 per quart. Not bad for something that keeps your wood looking sharp for years.

Key Differences Between Lacquer and Polyurethane

Lacquer and polyurethane protect wood in totally different ways. Polyurethane lays down a thick, plastic-like layer on the surface, while lacquer soaks in and bonds with the wood itself. You’ll notice big differences in how they look and how you need to apply them.

Durability and Protective Qualities

Polyurethane is the heavy-duty option. It shrugs off scratches, water, and heat, so it’s perfect for floors, tables, and anything you use a lot. That thick coating is like armor.

Lacquer protects, but it’s a softer touch. It soaks into the wood, which looks great, but it can chip or crack more easily. Heat and chemicals can mess it up faster than they would polyurethane.

In high-traffic spots, polyurethane just lasts longer—sometimes a decade or more if you apply it right.

Lacquer is better for furniture and cabinets that don’t get beat up every day. It’s a solid choice for lighter-duty stuff.

Appearance and Gloss Levels

Lacquer is famous for its high-gloss, glassy finish. That mirror-like shine is why furniture makers love it.

You can go for less shine, but lacquer’s gloss is what people notice. It also keeps the wood’s natural feel—doesn’t get plasticky.

Polyurethane comes in gloss, semi-gloss, satin, or matte. Oil-based versions turn yellow over time, which can change the look. Water-based stays clear, so your wood keeps its color.

Some folks think polyurethane feels a bit artificial, especially in thick coats. Lacquer keeps things more natural.

Application Methods Compared

Lacquer is best sprayed. It dries so fast—sometimes in 10 minutes—you have to move quick. Brushing is possible, but it’s tricky and can leave marks if you’re not careful.

Polyurethane is usually easier to brush or roll. The slower drying time means you have more time to fix mistakes and get things smooth. You can spray it, but most people just brush it on.

Quick comparison:

- Lacquer: Spray it on, dries in 10–30 minutes

- Polyurethane: Brush it on, dries in 4–24 hours

Lacquer doesn’t need sanding between coats, since each layer melts into the last. Polyurethane usually does—just a quick scuff to help it stick.

Advantages and Disadvantages

Both lacquer and polyurethane have their strong points and downsides. Lacquer is all about speed and a beautiful finish. Polyurethane wins for protection and all-purpose use. Honestly, the best choice depends on what you’re making and how it’ll get used.

Benefits of Lacquer

Lacquer is easily one of the fastest-drying wood finishes out there. You can apply several coats in just one day—each coat dries in about 10 minutes and you’re ready to recoat after 30.

The application feels pretty effortless. Every new coat blends right into the one before it, so you get a seamless finish without those annoying brush marks. Usually, there’s no need to sand between coats, unless something goes wrong.

Key lacquer advantages:

- Lightning-fast drying time

- No sanding required between coats

- Professional, smooth appearance

- Excellent for high-end furniture

- Self-leveling properties

Lacquer leaves a beautiful, clear finish that doesn’t pile up on your wood. That’s perfect if you want the natural wood grain to shine—great for detailed projects.

Its thin consistency lets you apply it with precision. You can get that glassy, mirror-like look that woodworkers are always chasing for their best work.

Pros and Cons of Polyurethane

Polyurethane is hard to beat when it comes to durability. It forms a thick shield that shrugs off scratches, water, heat, and even chemical spills better than most finishes.

Polyurethane advantages:

- Superior scratch and scuff resistance

- Excellent water protection

- Heat resistant properties

- Long-lasting durability

- Works on interior and exterior surfaces

This tough finish can protect your projects for over a decade if you keep up with basic care. It’s a go-to for high-traffic zones like floors and kitchen counters.

Polyurethane disadvantages:

- Slow drying time (4-24 hours between coats)

- Requires sanding between applications

- Can show brush marks and streaks

- Thick application may hide wood details

- Oil-based versions yellow over time

Polyurethane’s thickness makes it trickier to apply smoothly. Brush marks and dust can be a headache while it dries.

Best Uses and Recommendations by Project Type

Let’s be real: different projects need different finishes. Lacquer shines on furniture that needs a flawless, glossy look. Polyurethane is the workhorse for floors and spots that take a beating.

Furniture and Fine Woodworking

Lacquer is usually your best bet for most furniture and woodworking projects. It sprays on evenly and gives you that pro-level finish that makes furniture stand out.

Cabinets, desks, bookcases—they all benefit from lacquer’s speedy drying. You can knock out several coats in one day and move on.

Modern furniture really pops with lacquer’s high-gloss finish. The shine highlights the wood grain and gives your work that showroom vibe.

Lacquer penetrates deep into the wood, creating a solid bond that holds up over time.

Key benefits for furniture:

- Dries in minutes, not hours

- Easy to touch up scratches without sanding

- Perfect for spray application

- Maintains wood’s natural color

If your workshop’s not well-ventilated, water-based lacquer is a solid choice—it’s got less odor and fewer fumes than oil-based kinds.

Floors and High-Traffic Surfaces

Polyurethane is the clear winner for wood floors and surfaces that see a lot of action. It forms a tough, plastic-like layer that can take on shoes, pets, and daily wear.

Hardwood floors need that extra shield from polyurethane. Its thickness means you need fewer coats for solid coverage.

Pick your gloss level for the job:

- Satin or semi-gloss for floors (hides scratches better)

- High-gloss for tabletops (easier to clean)

Water-based polyurethane is great for indoor projects. It dries faster and doesn’t mess with your wood’s color like oil-based does.

Oil-based polyurethane gives you the toughest finish, but you’ll need patience—it dries slow. Use it where you need max protection.

Best applications include:

- Hardwood flooring

- Kitchen countertops

- Tabletops and dining surfaces

- Stair treads and handrails

Applying polyurethane doesn’t require fancy tools—a brush, roller, or even a rag will do. No need for spray equipment like lacquer.

Outdoor Furniture and Weather Exposure

Lacquer deals with outdoor conditions better than polyurethane. It sinks into the wood and flexes as the temperature changes, moving with the wood instead of just sitting on top.

Your outdoor furniture faces all sorts of abuse—heat, cold, rain, and sun. Over time, those elements will break down any finish.

Polyurethane tends to crack and peel outside. Its hard, plastic shell can’t flex as the wood expands and contracts in the weather.

Lacquer’s outdoor perks:

- Soaks into wood for a stronger bond

- Moves with temperature changes

- Easy to touch up—no full refinishing needed

- Less likely to peel or crack

But lacquer isn’t perfect outdoors. It can change color as it ages and needs more frequent touch-ups than indoor finishes.

If your outdoor furniture sits in a covered area (like a porch), polyurethane might still work. Less direct weather means it won’t fail as quickly.

Go with lacquer for:

- Deck furniture

- Outdoor dining sets

- Garden benches

- Boat projects

All outdoor finishes need regular upkeep. Plan to recoat every year or two, depending on how much sun and rain your stuff gets.

Choosing the Right Finish: Factors to Consider

Lacquer and polyurethane each need their own care routines and come with different health concerns. Knowing what kind of maintenance and safety they require will help you pick the right wood finish for your job.

Maintenance and Repair

Lacquer is way easier to fix up than polyurethane. If you get a scratch or ding, just spray a fresh coat over it. The new lacquer melts into the old and you’re good as new.

Polyurethane makes you work harder for repairs. You’ll have to sand the spot, then put on a new coat. These repairs can end up thicker and sometimes stick out on your surface.

For everyday cleaning, both finishes are fine with a little mild soap and water. Lacquer hides dust better but scratches show up quickly. Polyurethane shrugs off scratches but every bit of dust and fingerprints seem to stick.

Lacquer needs more frequent touch-ups in busy spots. Polyurethane holds up longer between refinish jobs, so it’s a better fit for homes with kids or pets running around.

Get the Fail-Safe Paint Color Playbook (Free PDF)

36 proven colors • 8 ready palettes • trim & sheen guide • printable testing cards.

Health, Safety, and Environmental Considerations

Lacquer contains a lot of VOCs (volatile organic compounds). You’ll want a proper respirator and good ventilation—ideally, work outside if you can.

Water-based polyurethane is much safer. It barely smells and cleans up with soap and water. Oil-based polyurethane has more fumes, but still less than lacquer.

Lacquer fumes can give you headaches or breathing issues. Pregnant women should absolutely skip lacquer projects. Keep kids and pets away while you’re applying and until it’s dry.

Once cured (usually about 30 days), both finishes are safe. Just keep your space aired out while they’re drying.

Environmental impact depends on the type. Water-based products are kinder to the planet. Look for low-VOC labels if you’re trying to stay green.

Frequently Asked Questions

People always have questions about how lacquer and polyurethane hold up in real life. Most want to know about durability, which works best for tables, how to apply them, and what kind of upkeep they’ll face.

What are the distinct durability differences between lacquer and polyurethane?

Polyurethane sets up a thicker, more plastic-like shell that stands up to heavy use better than lacquer. It’s great for high-traffic spots like floors or kitchen counters—ideal if you’ve got kids or pets.

Lacquer is durable, but the layers are thinner and scratch more easily, especially on surfaces you use every day. On the plus side, you can repair lacquer quickly since new coats blend into the old finish.

If you’re working outdoors, honestly, neither is the best. Varnish handles sun and weather much better for decks or patio furniture.

Can you explain which is better for a tabletop finish, lacquer or polyurethane?

Polyurethane is the go-to for dining and kitchen tables that get a lot of use. Its thick, tough layer protects against water rings, scratches, and daily messes. You can wipe up spills without stressing.

Lacquer looks fantastic on decorative or coffee tables that don’t see much action. It brings out the wood’s beauty and feels smooth, but isn’t as tough against hot dishes or constant use.

Think about how you’ll use your table. If it’s for everyday meals, go with polyurethane. If it’s more for looks, lacquer is lovely.

How do lacquer finishes compare to polyurethane ones on dining tables?

Dining tables take a beating from food, heat, and cleaning. Polyurethane’s thick coating stands up to all that much better than lacquer’s thin layers.

Lacquer is gorgeous on a dining table, but you’ll need to be careful—placemats and trivets are a must. Water rings and heat marks show up fast with lacquer.

Polyurethane lets you relax and use your table without fuss. It means less maintenance and fewer repairs over the years. For most dining rooms, it’s just the practical pick.

What are the main differences in application between lacquer and polyurethane?

Lacquer dries super fast—sometimes in just 5 minutes, and usually within 30. That quick drying keeps dust from sticking to the finish.

Polyurethane takes longer—water-based versions need 2 to 4 hours, and oil-based can take up to 24 hours between coats. You’ll need to plan ahead if you’re using polyurethane.

You have to sand between polyurethane coats for good results. With lacquer, you can skip that step since new coats fuse into the old. That’s a real time-saver.

Could you clarify when to use lacquer instead of polyurethane for wood projects?

Pick lacquer for fine furniture like jewelry boxes, art pieces, or cabinets that won’t get a ton of wear. It really brings out the grain and gives a sleek, pro look.

Get the Fail-Safe Paint Color Playbook (Free PDF)

36 proven colors • 8 ready palettes • trim & sheen guide • printable testing cards.

Lacquer is also the choice if you’re in a hurry. The fast drying means you can finish a project in a day—handy for small jobs or tight deadlines.

It’s also great for things people touch a lot, like wooden figurines or picture frames. The finish feels smooth and is easy to fix if it gets scratched.

Is there a significant difference in the maintenance of lacquer versus polyurethane finishes?

Lacquer repairs are usually a breeze compared to polyurethane. If you get a scratch, you can just dab on some new lacquer—it sort of melts into the old finish, making the repair almost invisible. Pretty convenient, honestly.

Polyurethane’s a different story. Its thick, plastic-like layer resists blending, so fixing damage gets tricky. Most times, you have to sand down the area before touching it up, which can be a hassle and takes a bit of practice.

Cleaning? Both finishes are low-maintenance with a little soap and water. But lacquer prefers a gentle touch; harsh cleaners might wreck its thinner coating. Polyurethane, on the other hand, shrugs off stronger cleaning products.